This was a 2001 Peugeot 406 2.0L petrol with a complaint of misfire, and it came with one of the most comprehensive shopping lists I’ve seen including: new plugs, new aftermarket coil pack, new genuine coil pack, new CKP sensor, replacement fuel pump, replacement fuel pump relay, replacement O2 sensor… and a partridge in a pear tree. The vehicle owner had a go at fixing it himself and the source of this wisdom came from online forums; god bless those forums. With a checklist of replacement parts already fitted, this should make it easier to diagnose. Wrong! Not only are you chasing someone else’s work, you are also having to deal with any problems inherited by interfering with those parts. You can only start at the beginning and fix as you find.

It was evident the misfire was fairly constant and didn’t seem dependent on engine load or temperature. ADTC check revealed a list as long as the replacement parts, none of which could be trusted based on the previous work so it was best to erase everything and start afresh. With the misfire present, the engine was run whist monitoring DTCs and live serial data. Each parameter seemed in line with normal values and there were no DTCs yet either. The PIDs worth mentioning were the HEGO predominantly hanging low and the fuel trims creeping up, which correlated with a misfire present and indicated unburnt oxygen entering the exhaust gas.

A power balance check isolated the problem cylinder to no.3 with the remaining cylinders pulling an even share of the running. A series of checks eliminated air flow, ignition and compression, which left only fuel delivery as the likely suspect. The next step was to verify the signal arriving at cylinder 3 injector.

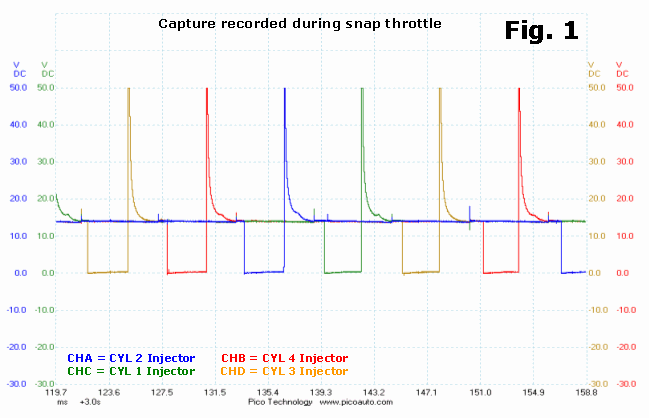

Fig.1 shows a collective view monitoring each negative pulse arriving at the 4 injectors. With any problem it’s best to collect as much information about the fault as possible. Viewing all of the injectors will help towards comparable analysis. At the moment this only represents signal voltage but it’s a good start. We are looking for something different associated to cylinder 3 injector operation. The checks include:

- Clean switching

- Good ground level achieved

- Pulse duration

- Current consumption

- Pintle activity

- Fuel flow (with the help of a pressure transducer hooked to the fuel rail)

Analysing the capture already recorded in Fig.1 we can quickly run through some checks to eliminate possible causes.

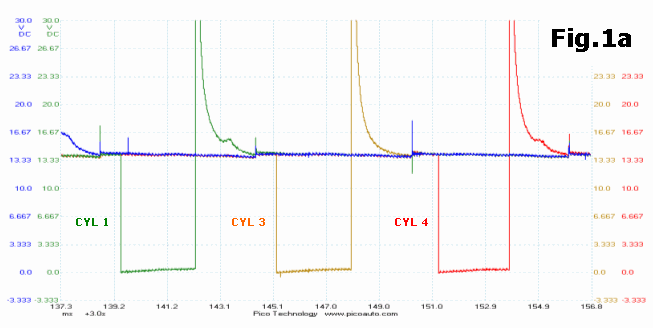

Concentrating on our suspect cylinder 3 injector, the driver shows a clean switch to ground and the ground level itself is good. Injector pulse duration is in line with companion cylinders and the driver release is clean. Furthermore, the ground pulse was examined and gave a reasonable indication that the circuit integrity was good. This is backed up by the healthy inductive kick as the injector coil field collapses

Attention is drawn to the slight notch towards the end of the inductive kick. This notch occurs as the injector pintle moves through the collapsing field and finally closes. Notice that only cylinder 3 notch is missing. This is an indication that the pintle is sticking either shut or open. Since there was no excessive HC content from the tailpipe then the focus of the investigation now turned to the pintle sticking closed. To further verify the fault, we need more information about circuit current. Where the voltage trace shows us when the pintle closed, it’s the current trace that shows us when the pintle opened.

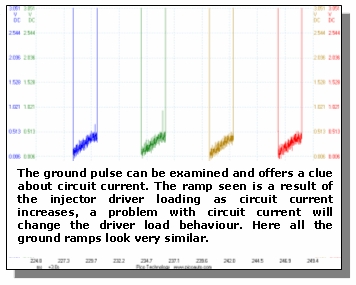

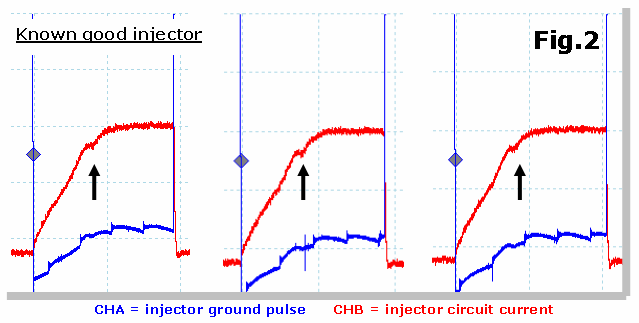

Fig.2 is a typical recording captured from a known good injector on a neighbouring cylinder and clearly shows a repetitive and stable pattern surrounding pintle activity.

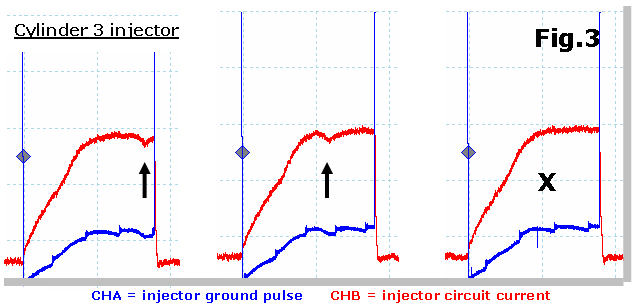

Fig.3 displays very different results showing the pintle fluctuating erratically and, worse, not opening at all. It follows that this delay in opening will significantly reduce the fuel quantity delivered to cylinder 3. The closed-loop fuelling is not cylinder-conscious: with the HEGO reporting a general lean condition, the ECM’s response is to add to the fuel trim until it sees the HEGO swing.

A new injector cured this complaint.

End note

Surprisingly the customer took the final answer in disbelief: the four purring cylinders clearly weren’t enough. His testing eliminated the injectors early on by removing the rail and cranking the engine to see if the injectors spewed fuel, and they did, so he continued with the elimination process resulting in an expensive ghost hunt.

Having the ability to show before and after snapshots is a strong ally.

其它辅导资料 >

|